Industry Overview

BeginnerGenerative AI is rapidly transforming the additive manufacturing industry, though adoption remains in the early to middle stages across most sectors. This emerging landscape is characterized by a mix of experimental applications, early commercial solutions, and a growing ecosystem of tools and platforms.

Current State at a Glance:

- Adoption Stage: Early-to-mid adoption with significant growth acceleration since 2022

- Market Size: The global market for GenAI in AM is projected to reach $2.1B by 2026, growing at ~45% CAGR

- Industry Leaders: Aerospace, medical, automotive, and consumer products at the forefront

- Technology Integration: Increasing integration with traditional AM software platforms and workflows

- Research Activity: Significant academic and commercial R&D with rapid publication growth

The convergence of generative AI and additive manufacturing is creating new possibilities while addressing longstanding challenges in AM adoption. This section explores the current landscape across applications, technology adoption, market trends, and emerging directions.

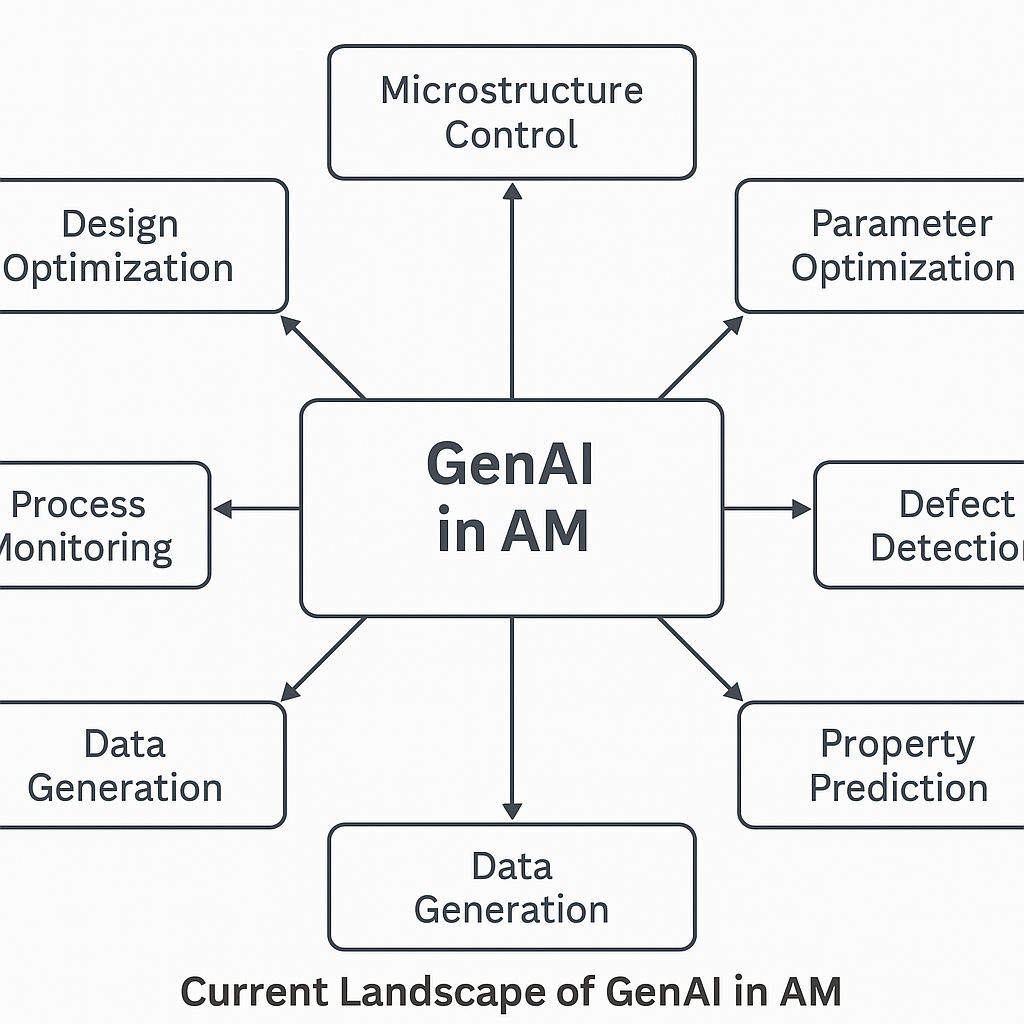

Existing Applications

BeginnerGenerative AI is already being applied across the additive manufacturing workflow, with varying levels of commercial maturity. These applications demonstrate the range of possibilities and current implementation status.

Design Generation

AI-driven creation and optimization of 3D models based on functional requirements and design constraints.

Process Optimization

Intelligent selection and adjustment of printing parameters based on part geometry, material, and quality requirements.

Quality Control

Real-time monitoring and defect detection systems using computer vision and predictive analytics.

Commercial Implementation Examples

Aerospace

- Topology Optimization: Lightweight structural components for aircraft with 30-50% weight reduction

- Thermal Management: Optimized cooling channels for engine components

- Consolidated Assemblies: Complex multi-part assemblies redesigned as single components

Medical

- Customized Implants: Patient-specific implants generated from medical imaging data

- Lattice Structures: Bone-mimicking structures with optimized porosity and mechanical properties

- Surgical Guides: Personalized tools to improve surgical precision

Automotive

- Lightweight Components: Performance-optimized brackets, mounts, and structural parts

- Fluid Systems: Optimized manifolds and fluid handling components

- Tooling: AI-designed conformal cooling channels in injection molds

Consumer Products

- Mass Customization: Personalized products based on individual user data

- Performance Optimization: Sports equipment with enhanced performance characteristics

- Complex Geometries: Aesthetically distinctive designs with functional benefits

Examples of commercially deployed GenAI applications in additive manufacturing

Technology Adoption

IntermediateThe adoption of generative AI technologies in additive manufacturing is progressing at different rates across various industry segments and application areas. Understanding these adoption patterns provides context for current capabilities and future development.

Adoption by Industry Segment

| Industry | Adoption Level | Primary Applications | Key Drivers |

|---|---|---|---|

| Aerospace | High (70-85%) | Topology optimization, thermal design | Weight reduction, performance enhancement |

| Medical | High (65-80%) | Custom implants, surgical planning | Patient customization, improved outcomes |

| Automotive | Moderate (40-60%) | Lightweighting, tooling optimization | Cost reduction, production efficiency |

| Consumer Goods | Moderate (35-55%) | Customization, novel designs | Market differentiation, performance |

| General Manufacturing | Low-Moderate (20-40%) | Tooling, fixtures, prototyping | Cost reduction, production flexibility |

| Construction | Low (10-25%) | Architectural elements, structural optimization | Material efficiency, design freedom |

Adoption by Technology Type

Different generative AI approaches are being adopted at varying rates in the AM industry:

Widely Adopted (60-80%)

- Topology Optimization: Well-established design approach with clear ROI

- Parameter Recommendation Systems: Improving print success rates and part quality

- Computer Vision for Quality Control: Detecting common defects in production

Growing Adoption (30-60%)

- Generative Design Exploration: Creating multiple design alternatives

- Lattice Structure Optimization: Balancing weight, strength, and material usage

- Process Simulation: Predicting build outcomes and potential issues

Early Adoption (10-30%)

- Text-to-3D Generation: Creating initial designs from textual descriptions

- Multi-material Optimization: Designing with multiple materials for optimal properties

- Autonomous Manufacturing Agents: Systems that manage multiple aspects of the AM workflow

Experimental (5-15%)

- 4D Printing Design: AI-designed components that change shape after printing

- Microstructure Engineering: Controlling material properties at the microscale

- Closed-Loop Cognitive Manufacturing: Self-optimizing production systems

Market Trends

IntermediateThe market for generative AI in additive manufacturing is evolving rapidly, with several key trends shaping the landscape and future direction of the industry.

Market Growth and Projections

The global market for GenAI solutions in AM is experiencing significant growth:

- Current estimated market size (2024): ~$650M USD

- Projected annual growth rate: 40-50% CAGR through 2030

- Projected market size by 2030: $5.8-7.2B USD

- Fastest growing segment: Design optimization tools (55% CAGR)

- Most established segment: Process parameter optimization (35% CAGR)

Growth projection for GenAI in AM market segments (2024-2030)

Key Market Trends

Industry Consolidation

Major AM hardware and software companies are acquiring AI startups to enhance their offerings. This trend is accelerating with:

- 12 significant acquisitions in the past 24 months

- Strategic partnerships between AM leaders and AI companies

- Integration of GenAI capabilities into established AM platforms

Specialized Solution Providers

Despite consolidation, specialized GenAI providers are emerging in niche areas:

- Industry-specific design generation (medical, aerospace)

- Material-specific optimization engines

- Process-specific monitoring and control systems

- Custom LLM implementations for AM knowledge

Investment and Funding

The GenAI in AM sector is attracting significant investment:

- Venture Capital: $450M+ invested in GenAI-focused AM startups in the past 18 months

- Corporate R&D: Major manufacturers increasing internal AI/AM R&D budgets by 30-45%

- Government Funding: Public research initiatives in US, EU, and Asia totaling $280M+ for AI in manufacturing

- Valuation Trends: GenAI in AM startups commanding 2-3x higher valuations than traditional AM software companies

Current Challenges

AdvancedDespite significant progress, several challenges are currently limiting the full potential of generative AI in additive manufacturing. Understanding these challenges provides context for current limitations and areas requiring further development.

Technical Challenges

- Limited Training Data: Insufficient labeled datasets specific to AM processes and materials

- Physics Integration: Balancing data-driven approaches with physics-based constraints

- Computational Requirements: High resource demands for complex simulations and optimizations

- Multi-Scale Optimization: Addressing micro, meso, and macro scales simultaneously

- Process Variability: Accounting for inherent variability in AM processes when making predictions

Implementation Challenges

- Integration Complexity: Connecting GenAI solutions with existing AM software ecosystems

- Validation Approaches: Establishing reliable methods to validate AI-generated designs

- Skills Gap: Shortage of professionals with expertise in both AM and AI

- Cost Barriers: High implementation costs for comprehensive GenAI solutions

- Legacy Systems: Integration with established manufacturing infrastructure

Business Challenges

- ROI Demonstration: Proving concrete return on investment for GenAI adoption

- Intellectual Property: Unclear frameworks for AI-generated designs and methods

- Regulatory Uncertainty: Evolving compliance requirements for AI in critical applications

- Risk Management: Establishing appropriate oversight and validation for AI systems

- Change Management: Organizational resistance to new design and manufacturing approaches

Ongoing Research Areas

- Explainable AI: Making GenAI decisions transparent and interpretable

- Transfer Learning: Applying knowledge from one domain to another with minimal data

- Online Learning: Continuously improving models during the manufacturing process

- Uncertainty Quantification: Reliable confidence metrics for AI predictions

- Multi-Objective Optimization: Balancing competing requirements effectively

# Pseudocode for multi-physics aware GenAI model

class MultiPhysicsAwareDesignGenerator:

def __init__(self):

self.thermal_model = ThermalPredictionModel()

self.mechanical_model = MechanicalPerformanceModel()

self.manufacturability_model = PrintabilityModel()

self.design_generator = DiffusionDesignModel()

def generate_design(self, requirements, constraints):

# Initial design generation

initial_designs = self.design_generator.sample_designs(

requirements=requirements,

num_samples=10

)

validated_designs = []

for design in initial_designs:

# Multi-physics validation

thermal_results = self.thermal_model.predict(design)

mechanical_results = self.mechanical_model.predict(design)

printability_results = self.manufacturability_model.predict(design)

# Check against constraints

thermal_valid = self.check_thermal_constraints(thermal_results, constraints)

mechanical_valid = self.check_mechanical_constraints(mechanical_results, constraints)

printable = self.check_printability_constraints(printability_results, constraints)

if thermal_valid and mechanical_valid and printable:

validated_designs.append({

"design": design,

"thermal_performance": thermal_results,

"mechanical_performance": mechanical_results,

"manufacturability": printability_results

})

# Rank and return the best design

if validated_designs:

return self.rank_designs(validated_designs, requirements)

else:

# Feedback loop to refine generation process

return self.refine_and_regenerate(initial_designs, constraints)

Emerging Directions

AdvancedSeveral emerging directions are shaping the future landscape of generative AI in additive manufacturing. These developments are in various stages of research, early implementation, or commercial introduction.

Technical Advancements

Multi-Material & Multi-Process Optimization

Beyond single material design to optimize material distribution and process parameters simultaneously across multiple materials and manufacturing methods.

Autonomous Manufacturing Agents

AI systems that manage the entire AM workflow, from design interpretation to final quality verification, with minimal human intervention.

Natural Language Design Interfaces

Conversational interfaces allowing users to describe functional requirements in natural language and receive optimized designs.

Convergence with Other Technologies

The integration of GenAI with other emerging technologies is creating powerful new capabilities:

GenAI + Digital Twins

Virtual representations that combine real-time data with predictive capabilities:

- Dynamic prediction of part quality during printing

- Real-time process parameter adjustments

- Continuous learning from operational feedback

- Virtual testing of designs before physical production

GenAI + Robotics

Autonomous systems that combine physical capabilities with intelligence:

- Adaptive path planning for robotic deposition

- Autonomous post-processing operations

- Multi-robot coordination for large-scale printing

- Self-calibrating manufacturing systems

Research Frontiers

Advanced research is exploring several promising directions that may reshape AM capabilities:

- Microstructure Design: AI-driven control of material properties at the microscale level

- Process-Aware Design: Design systems that incorporate process physics during generation

- Bio-Inspired Generative Systems: Learning from natural growth processes to create optimized structures

- Quantum-Enhanced Optimization: Using quantum computing to address complex multi-objective optimization challenges

- Human-AI Collaborative Design: Interactive systems where human designers and AI work together seamlessly

Ready to Explore Cutting-Edge Applications?

Discover how these emerging technologies are being applied in real-world manufacturing contexts: