Understanding Agent-Based Systems

BeginnerAgent-based systems have revolutionized industries such as communication, business, and manufacturing by providing adaptability, scalability, and real-time decision-making in complex environments. In manufacturing, they automate tasks ranging from product design to supply chain management to support the basic principles of Industry 4.0.

This research explores how Generative AI can enhance agent-based systems for manufacturing applications, with a particular focus on additive manufacturing processes.

Key Concepts:

- Agent Autonomy: The ability to act independently to achieve goals

- Multi-Agent Systems: Networks of agents collaborating to solve complex problems

- Generative Capabilities: Creating new solutions rather than selecting from predefined options

- Contextual Understanding: Processing and responding to complex manufacturing scenarios

- Adaptability: Learning from feedback and improving performance over time

Traditional vs. GenAI Agents

BeginnerTraditional agents, while precise and reliable for structured tasks, face limitations in flexibility and adaptability to dynamic or unstructured environments. A new type of agent, the Generative Artificial Intelligence (GenAI) agent, dramatically alters the landscape of agent-based systems by offering enhanced capabilities.

| Characteristic | Traditional Agents | GenAI Agents |

|---|---|---|

| Task Handling | Narrow, well-defined tasks | Versatile, can adapt to diverse tasks |

| Knowledge Base | Explicitly programmed rules | Learned patterns from large datasets |

| Communication | Structured formats, limited natural language | Advanced natural language understanding |

| Adaptability | Requires reprogramming for new scenarios | Can adapt to novel situations |

| Data Types | Primarily structured data | Can process unstructured and multi-modal data |

| Learning | Limited or no learning capabilities | Continuous improvement through feedback |

Powered by increasingly sophisticated GenAI models, GenAI agents can integrate multiple roles, enhance automation, and introduce capabilities beyond the scope of traditional agents, establishing themselves as critical enablers for modern manufacturing ecosystems.

GenAI Agent Capabilities

IntermediateGenAI agents bring several distinctive capabilities to manufacturing environments that differentiate them from traditional agent-based systems:

Versatility and Adaptability

GenAI agents demonstrate remarkable versatility across diverse manufacturing scenarios:

- Handling multiple types of manufacturing tasks without reprogramming

- Adapting to changing manufacturing requirements and constraints

- Transferring knowledge between related manufacturing domains

- Continuous improvement through operational feedback

Contextual Understanding

The ability to understand complex manufacturing contexts is crucial:

- Interpreting technical specifications and requirements

- Understanding relationships between manufacturing parameters

- Recognizing implicit constraints and domain knowledge

- Maintaining awareness of the overall manufacturing process

Unstructured Data Handling

Processing diverse data types common in manufacturing environments:

- Natural language descriptions and requirements

- Technical documentation and knowledge bases

- Visual data from inspection systems and cameras

- Time-series data from sensors and monitoring systems

Generative Problem-Solving

Creating novel solutions rather than selecting from predefined options:

- Generating optimized manufacturing parameters

- Creating new design alternatives to meet requirements

- Developing troubleshooting approaches for novel issues

- Synthesizing insights from disparate data sources

Manufacturing Applications

IntermediateGenAI agents can be applied across various aspects of the manufacturing process, with particular relevance to additive manufacturing due to its complexity and data-rich nature.

Additive Manufacturing Applications

Design Optimization

GenAI agents can generate and optimize designs specifically for AM processes, incorporating build constraints while maximizing performance.

Process Parameter Selection

Agents can determine optimal printing parameters based on part geometry, material properties, and quality requirements.

Quality Monitoring

Real-time monitoring agents can detect anomalies during printing and either adjust parameters or alert operators.

Broader Manufacturing Applications

- Predictive Maintenance: Monitoring equipment health and predicting maintenance needs

- Supply Chain Optimization: Managing inventory and logistics based on production demands

- Production Scheduling: Optimizing manufacturing schedules for efficiency and throughput

- Knowledge Management: Capturing, organizing, and applying manufacturing knowledge

- Human-Machine Collaboration: Facilitating communication between operators and manufacturing systems

Implementation Considerations

AdvancedImplementing GenAI agents in manufacturing environments requires careful consideration of several factors to ensure successful integration and operation.

Technical Considerations

- Model Selection: Choosing appropriate foundation models for specific manufacturing tasks

- Fine-Tuning: Adapting models to manufacturing-specific knowledge and terminology

- Integration: Connecting agents with existing manufacturing systems and data sources

- Computational Requirements: Ensuring sufficient resources for model inference and operation

- Data Management: Handling the flow of information between agents and manufacturing systems

Operational Considerations

- Reliability: Ensuring consistent agent performance in production environments

- Safety: Implementing safeguards to prevent unintended actions or recommendations

- Validation: Verifying agent outputs against established quality standards

- Human Oversight: Defining appropriate levels of human supervision and intervention

- Performance Metrics: Establishing KPIs to evaluate agent effectiveness

Architectural Approaches

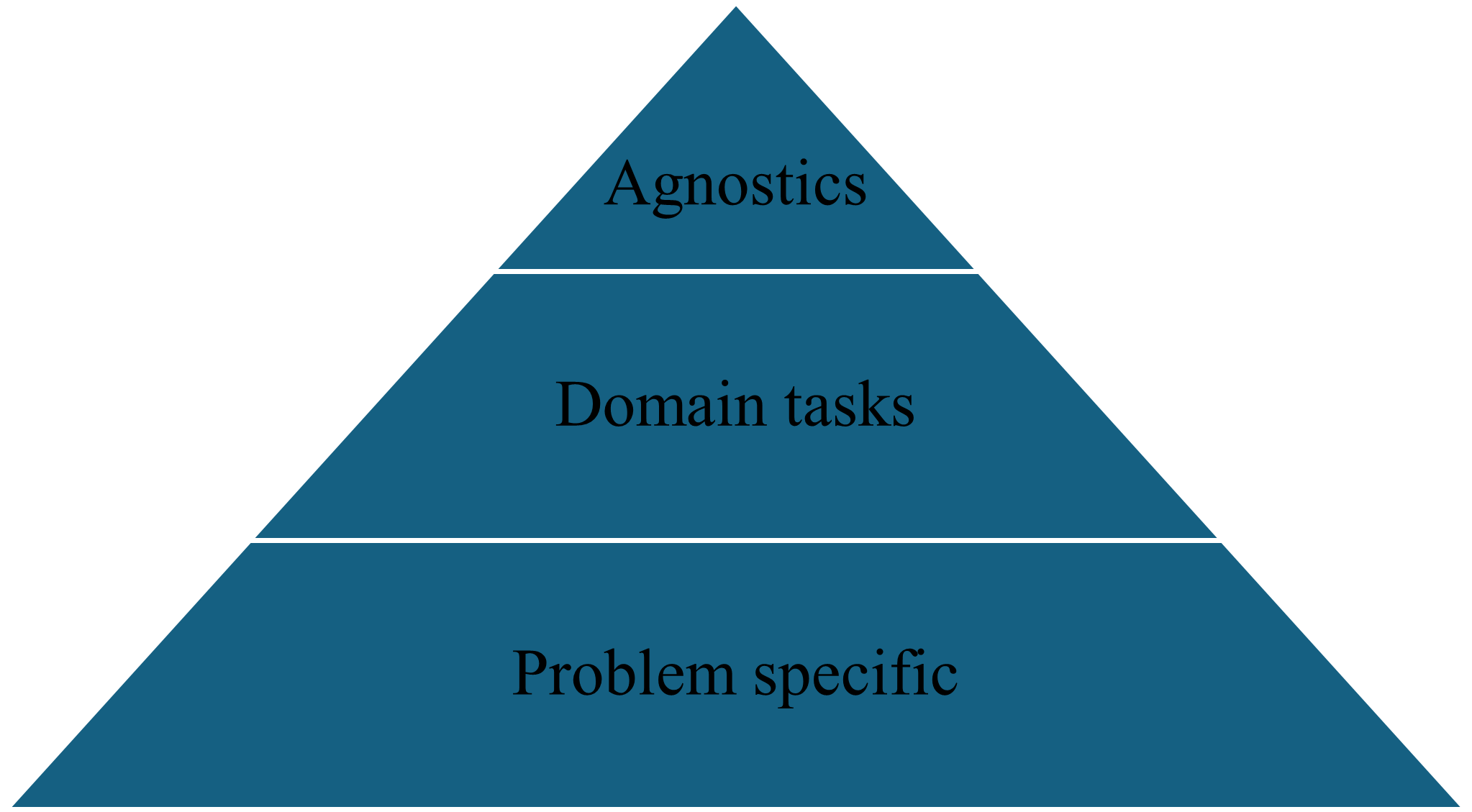

Several architectural patterns have emerged for implementing GenAI agents in manufacturing:

- Centralized Agent Systems: A single agent coordinating multiple manufacturing functions

- Distributed Multi-Agent Systems: Multiple specialized agents collaborating through defined protocols

- Hierarchical Agent Structures: Layered agent systems with supervisory and operational levels

- Hybrid Human-AI Systems: Collaborative frameworks where agents augment human capabilities

Research & Publications

AdvancedThis research on GenAI agent-based systems for manufacturing is conducted in collaboration with experts in both AI and manufacturing domains.

Research Team

This work is a collaboration between:

Publications

The research is currently under review for publication. Check back for updates on the publication status and links to the full research paper.

Explore GenAI Agent Applications

Discover how these foundational concepts are being applied in real-world manufacturing scenarios: